Manual Veit Fusing Machine

Manual Veit Fusing Machine Specification

- Drum Diameter

- 600 mm Millimeter (mm)

- Heating

- Electrically heated with precision thermostat

- Voltage

- 220V/380V, 50/60Hz Volt (v)

- Material

- Powder coated steel housing, conveyor belts with PTFE coating

- Control System

- Automatic digital control panel

- Installation Guideline

- Needs skilled technician; follow Veit manual

- Cleaning Method

- Manual wipedown and periodic vacuuming

- Fusing Belt Width

- 600 mm

- Pressure Range

- 0.1 to 0.6 N/cm

- Weight

- Approx. 250 kg

- Safety Features

- Emergency stop, overheat protection, safety covers

- Display Type

- Digital LED display

- Temperature Range

- 100C to 210C (adjustable)

About Manual Veit Fusing Machine

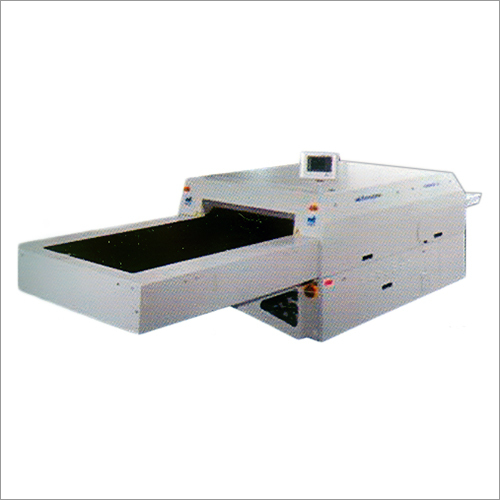

Veit Fusing Machine (Fx Diamond)

Features:- Optimal fusing results thanks to exact temperature control directly at the belt

- Consistent fusing results due to consistent pressure over the entire operating width

- Optimal adjustment of pressure system (soft, medium) and heating sequence (top, bottom) to the materials to be processed

- Perfectly designed service concept allows easy and regular cleaning of machine

- Lowest possible energy consumption due to: separate feeding belt, no cooling of transport belt outside of machine complete encapsulation of heating units for extremely low heat loss decoupling of heating zones from machine frame

- Separate feeding belt, no cooling of transport belt outside of machine

- Easy operating with new 7'' colour touch display

- Reduced wear and tear of belt edge through contact-free belt detection

- Prevention of faulty fusing through start/stop function in the event of a diversion from pre-set fusing parameters. This allows the operator to step in

- Consistent fusing quality due to optimized cleaning of the belts both on the inner and the outer side. Consequently, major reduction in soiling of roller and fusing material

Precision and Flexibility for Fabrics

With an adjustable temperature and pressure range, the Veit Fusing Machine provides controlled fusing for various garment materials. The precise digital LED display and smooth belt speed adjustment ensure accurate application, enhancing product quality and production consistency for exporters, importers, and manufacturers in India.

Safety and Operation Assurance

Operational safety is a priority with integrated emergency stop, overheat protection, and safety covers. The automated digital control panel minimizes operator error, promoting efficiency while protecting materials and users in demanding production environments.

Engineered for High Capacity

Featuring a wide 600 mm belt, high-capacity drum, and a robust powder-coated steel body, the Veit Fusing Machine delivers reliable continuous operation at speeds between 25 to 50 meters per minute. Perfect for large-scale garment and interlining processes.

FAQs of Veit Fusing Machine:

Q: How do I adjust the temperature and pressure settings on the Veit Fusing Machine?

A: Both temperature (100C to 210C) and pressure (0.1 to 0.6 N/cm) are adjusted easily using the automatic digital control panel and digital LED display, providing fine-tuned accuracy for various garment and interlining materials.Q: What safety features are included with the Veit Fusing Machine to protect users and materials?

A: The machine is equipped with an emergency stop, overheat protection, and comprehensive safety covers, ensuring heightened safety for operators and safeguarding fabrics during operation.Q: When should cleaning and maintenance be performed on the Veit Fusing Machine?

A: Manual wipedown and periodic vacuuming are recommended, especially after high-volume usage. Regular upkeep ensures optimal performance; always follow the maintenance schedule outlined in the Veit manual.Q: Where is the Veit Fusing Machine best suited for installation?

A: This machine is ideal for use in garment factories and textile production units. It is recommended that installation be performed by a skilled technician, following the official Veit guideline for safety and optimal operation.Q: What is the process for fusing interlining with this machine?

A: Place the materials on the conveyor belt, select the required temperature, pressure, and speed using the control panel, and allow the machines high-capacity drum to carry out the fusing process efficiently and evenly.Q: How does the variable speed drive benefit production flexibility?

A: The variable speed drive lets operators adjust conveyor speed between 25 to 50 meters per minute, accommodating different fabric types and production requirements, thus improving output efficiency and quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Veit Fusing Machine Category

Automatic Veit Fusing Machine

Voltage : 220V/380V, 50/60Hz

Material : Industrial grade steel body with nonstick, heatresistant conveyor belt

Cleaning Method : Easyaccess panels for quick maintenance and cleaning

Installation Guideline : Requires professional installation on a stable surface with proper ventilation

Heating : Infrared heating element with uniform heat distribution

Control System : Digital touch control panel with programmable temperature and time settings

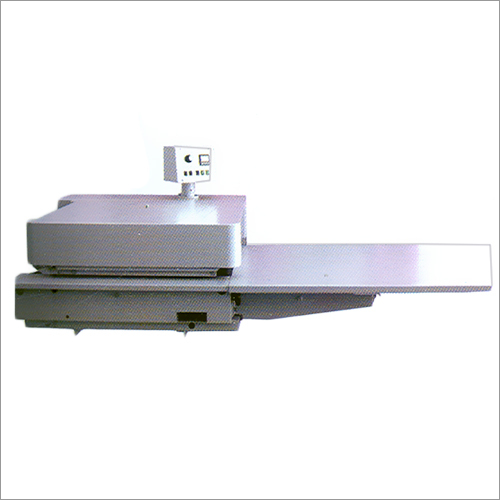

Manual Veit Fusing Machine

Voltage : 220V singlephase Volt (v)

Material : Metallic body

Cleaning Method : Manual cleaning

Installation Guideline : Follow manual guidelines

Heating : Electric heating

Control System : Analog control system

GST : 29AAACR8787Q1Z6

|

RAMSONS GARMENT FINISHING EQUIPMENTS (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry