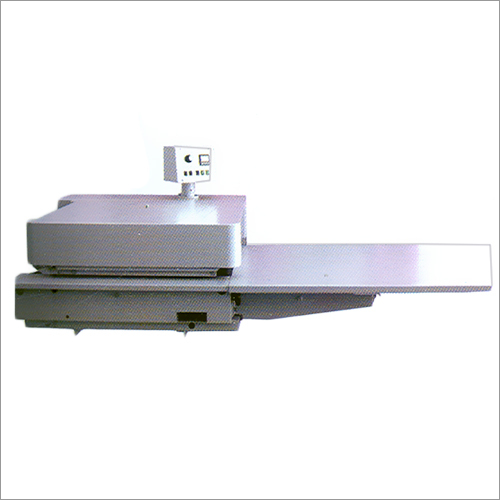

Automatic Veit Fusing Machine

Automatic Veit Fusing Machine Specification

- Drum Diameter

- 450 mm

- Drum Capacity

- 50 pieces per hour (garment-dependent)

- Heating

- Infrared heating element with uniform heat distribution

- Voltage

- 220V/380V, 50/60Hz

- Capacity

- Continuous operation for industrial scale garment production

- Material

- Industrial grade steel body with non-stick, heat-resistant conveyor belt

- Control System

- Digital touch control panel with programmable temperature and time settings

- Installation Guideline

- Requires professional installation on a stable surface with proper ventilation

- Cleaning Method

- Easy-access panels for quick maintenance and cleaning

- Display Type

- Large LED display for status and settings

- Net Weight

- Approx. 240 kg

- Noise Level

- <60 dB during operation

- Working Temperature Range

- 100°C to 200°C adjustable

- Conveyor Belt Width

- 600 mm

- Application

- Ideal for laminating, interlining, and fusing appliqué in garment manufacturing

- Dimensions (LxWxH)

- 1750 x 800 x 1200 mm

- Pressure System

- Pneumatic pressure with precise adjustment

- Safety Features

- Emergency stop button, overheat protection system

- Fusing Time Range

- 5 to 34 seconds, digitally adjustable

About Automatic Veit Fusing Machine

Veit Fusing Machine (Bx Series)

Features:

- Sturdy, compact design requires minimal floor space.

- Extended heat chamber.

- Rapid machine warm-up.

- Totally reliable and adjustable/maintains accurate temperature and pressure

Digital Precision and Safety

This fusing machine boasts a user-friendly digital touch control panel, enabling effortless adjustments for both temperature and fusing time. The large LED display clearly indicates all operational statuses. Enhanced safety is assured through the emergency stop feature and an overheat protection system, allowing for reliable and risk-free production in industrial garment settings.

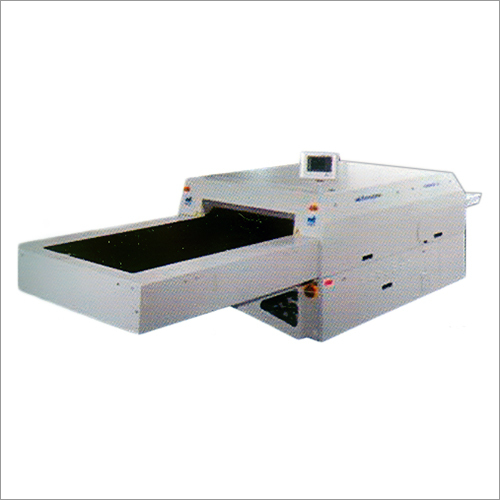

Robust Construction and Optimized Workflow

Constructed from industrial-grade steel and fitted with a non-stick, heat-resistant conveyor belt, the machine is built for durability and hygiene. The easy-access panels simplify cleaning and maintenance, while the 450 mm drum delivers a capacity of up to 50 pieces per hour, accommodating continuous production for demanding garment factories.

FAQs of Automatic Veit Fusing Machine:

Q: How do I set the correct temperature and fusing time on the Automatic Veit Fusing Machine?

A: The machine offers a digital touch control panel where you can precisely program the working temperature between 100C and 200C, as well as the fusing time from 5 to 34 seconds. The large LED display will show your selected settings, ensuring easy monitoring and adjustment during operation.Q: What types of fabric applications is this fusing machine designed for?

A: It is ideal for laminating, interlining, and fusing appliqu to various textiles, making it highly suitable for garment manufacturing processes where consistent quality and strong fabric bonds are essential.Q: When should I perform maintenance or cleaning on the machine?

A: To ensure optimal performance, it is recommended to conduct routine maintenance and cleaning, especially when changing materials or after daily production. Accessible side panels make it straightforward to clean the conveyor belt and internal parts.Q: Where should the Automatic Veit Fusing Machine be installed?

A: For safe and stable operation, the machine should be professionally installed on a flat, stable surface in a well-ventilated workspace. This helps maintain machine performance and ensures compliance with safety guidelines.Q: What process does the machine follow to ensure uniform heating and fabric adhesion?

A: The Veit fusing machine uses an infrared heating element that provides uniform heat distribution across the conveyor belt area. Controlled pneumatic pressure and programmable settings ensure that each fabric piece receives consistent heating and adhesion as it passes through the fusing zone.Q: How does the machine benefit an industrial garment facility?

A: The machine supports continuous, high-volume production with minimal noise (<60 dB) and efficient energy use. Its robust components and advanced safety features minimize downtime, enhance quality control, and increase overall productivity for garment exporters, importers, manufacturers, and suppliers.Q: What safety features are equipped on this fusing machine?

A: The machine includes an emergency stop button for immediate power-off and an overheat protection system to automatically shut down the heating unit if necessary, safeguarding both operators and production materials.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Veit Fusing Machine Category

Veit Fusing Machine

Heating : Electrically heated with precision thermostat

Capacity : 2550 meters/min (adjustable)

Control System : Automatic digital control panel

Installation Guideline : Needs skilled technician; follow Veit manual

Material : Powder coated steel housing, conveyor belts with PTFE coating

Voltage : 220V/380V, 50/60Hz

Manual Veit Fusing Machine

Heating : Electric heating

Capacity : 15 pieces per minute

Control System : Analog control system

Installation Guideline : Follow manual guidelines

Material : Metallic body

Voltage : 220V singlephase

RAMSONS GARMENT FINISHING EQUIPMENTS (P) LTD.

GST : 29AAACR8787Q1Z6

GST : 29AAACR8787Q1Z6

No.1/4, 1st Floor, Off Ulsoor Road, Hanumanthappa Layout, Sivanchetti Gardens,Bengaluru - 560042, Karnataka, India

Phone :07971405246

|

RAMSONS GARMENT FINISHING EQUIPMENTS (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry