Flexi Brushing Robo (Vertical & Horizontal Robo)

Flexi Brushing Robo (Vertical & Horizontal Robo) Specification

- Drum Diameter

- 750 mm

- Drum Capacity

- 100 L

- Heating

- Optional Electric or Steam Heating Arrangement

- Voltage

- 415 V, 3 Phase, 50 Hz

- Capacity

- Up to 10 Drums per Hour

- Material

- Stainless Steel 304/316

- Control System

- PLC Based Control System with Touch Screen Interface

- Installation Guideline

- Easy to Install Plug & Play Modules with Customizable Mounts

- Cleaning Method

- High-Speed Rotary Brushing (Both Vertical and Horizontal Axis)

- Water Consumption

- Adjustable, up to 120 Litres/Hour

- Automation Level

- Fully Automatic with Manual Override Option

- Noise Level

- Less than 70 dB(A)

- Weight

- Approx. 950 Kg

- Mobility

- Heavy Duty Casters with Locking Mechanism

- Finish

- Food Grade, Corrosion Resistant

- Dimensions

- 2100 mm (L) x 1200 mm (W) x 1850 mm (H)

- Safety Features

- Emergency Stop, Overload Protection, Enclosed Structure for Operator Safety

- Brushing Type

- Interchangeable Nylon and Stainless Steel Brushes

- Suitable Drum Range

- 20 Litres to 210 Litres Drums

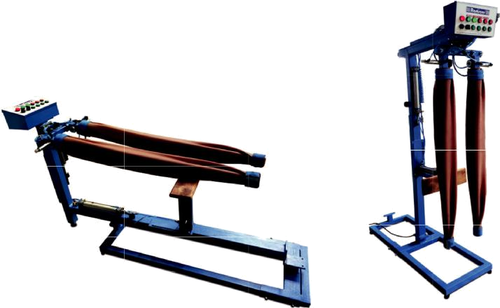

About Flexi Brushing Robo (Vertical & Horizontal Robo)

Flexi Brushing Robo (Vertical & Horizontal Robo) (70)

The Flexi Brushing Robo can be used for both horizontal and vertical brushing effects on denim trousers. It has a rugged frame with a hinge which can be easily interchanged.

Features:

- Automatic filling of air controlled by a precision pressure switch.

- Pneumatic air exhaust for fast release.

- Pneumatic lifting for easy loading and unloading.

- Automatic rotation with Pneumatic back knee support.

- Ergonomically designed control panel for easy operation.

Versatile and Powerful Drum Cleaning

The Flexi Brushing Robo combines vertical and horizontal high-speed rotary brushing for comprehensive drum cleaning. Its adaptable design accommodates a broad range of drum sizes and capacities, allowing users to swap between nylon and stainless steel brushes to suit different cleaning needs. With its fully automated PLC control and an intuitive touch screen interface, operations are streamlined for convenience as well as precision.

Advanced Safety and User-Friendly Operation

Operator safety is prioritized through features like an enclosed structure, emergency stop, and overload protection. Flexible mobility is provided via heavy-duty casters with locks, making it easy to position or relocate the unit as needed. The easy installation, with plug-and-play modules and customizable mounts, simplifies integration into various industrial setups. The low noise output and food-grade finish make it ideal for sensitive environments.

FAQs of Flexi Brushing Robo (Vertical & Horizontal Robo):

Q: How does the Flexi Brushing Robo achieve effective cleaning for different drum sizes?

A: The Flexi Brushing Robo is engineered with interchangeable brush types (nylon and stainless steel) and both vertical and horizontal rotary brushing actions. This allows thorough cleaning for drums ranging from 20 to 210 liters in capacity, easily adapting to the drum size and residue type.Q: What process is followed by the machine during operation, and can operators manually intervene if needed?

A: The machine uses high-speed rotary brushing along both axes to scrub internal drum surfaces. A fully automatic PLC-based control system manages the cleaning cycle, but operators can manually override the process as required via the touch screen, ensuring flexibility for specific cleaning needs.Q: When should the brushes be changed, and which types are suitable for particular residues?

A: Brushes should be inspected regularly and replaced when wear or reduced cleaning effectiveness is noticed. Nylon brushes are ideal for general or sensitive applications, while stainless steel brushes are preferred for tougher residues or in harsher industrial use.Q: Where can the Flexi Brushing Robo be installed within a facility, and is its installation complicated?

A: The unit features heavy-duty casters and a plug-and-play design with customizable mounts, making it easy to install in various production or maintenance areas. Installation is straightforward and does not require extensive modification to existing layouts.Q: What safety mechanisms are provided to protect operators during use?

A: The Flexi Brushing Robo is built with a fully enclosed structure, an emergency stop button, and overload protection. These features collectively safeguard operators by minimizing potential contact with moving parts and halting operation during abnormal conditions.Q: How do automation and adjustable water consumption benefit daily operation?

A: Automated controls ensure consistent cleaning results and reduce manual intervention, leading to increased productivity. Adjustable water consumption up to 120 litres/hour lets operators optimize resource usage based on drum condition, making the cleaning process both efficient and sustainable.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dry Process Equipment Category

Conveyorised Spraying System

Material : 304 Grade Stainless Steel

Cleaning Method : Integrated autorinse cycle with removable spray nozzles

Installation Guideline : Modular assembly; requires solid flooring and singlephase/threephase power source

Control System : PLCbased automated control panel for precise spray timing and conveyor speed

Heating : Electric heating elements with adjustable thermostat

Capacity : 1000 units per hour

Inclinde Brushing Mannequins

Material : Highquality PVC and synthetic hair

Cleaning Method : Wipe with damp cloth or mild disinfectant after use

Installation Guideline : Place mannequin on stable flat surface before use. Attach securely if required.

Control System : Manual Operation

Heating : No heating provided

Capacity : Single unit for demonstration

3d Flexible Mannequin

Material : Metal and polymer construction

Cleaning Method : Wipe with a damp cloth

Installation Guideline : Assemble per provided instruction manual

Control System : Manual

Heating : None

GST : 29AAACR8787Q1Z6

|

RAMSONS GARMENT FINISHING EQUIPMENTS (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry