Conveyorised Spraying System

Conveyorised Spraying System Specification

- Drum Diameter

- 600 mm

- Drum Capacity

- 250 liters per drum

- Heating

- Electric heating elements with adjustable thermostat

- Voltage

- 415V, 50Hz

- Capacity

- 1000 units per hour

- Material

- 304 Grade Stainless Steel

- Control System

- PLC-based automated control panel for precise spray timing and conveyor speed

- Installation Guideline

- Modular assembly; requires solid flooring and single-phase/three-phase power source

- Cleaning Method

- Integrated auto-rinse cycle with removable spray nozzles

- Safety Features

- Emergency stop switch, protective covers, safety interlock system

- Environmental Compliance

- Designed as per ISO 14001 standards

- Power Consumption

- 6.5 kW

- Noise Level

- < 80 dB

- Conveyor Speed

- Adjustable, up to 18 m/min

- Conveyor Type

- Continuous belt conveyor

- Spray Nozzle Type

- High efficiency air-assisted nozzles

- Number of Spray Stations

- 4

- Operating Temperature Range

- Ambient to 70°C

- Compatible Paint Types

- Water-based, solvent-based paints

- Dimensions

- 6000 mm (L) x 1200 mm (W) x 1850 mm (H)

- Weight

- 950 kg

- Application

- Surface coating and painting

- Finish

- Polished, corrosion-resistant

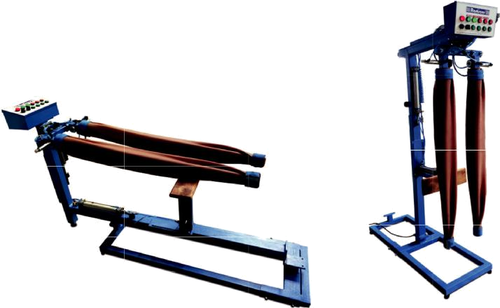

About Conveyorised Spraying System

Ramsons Conveyorised Spray Booth (75)

This is a complete PP spray booth with Conveyorized Mannequins & Hot chamber for higher productivity and better quality.

Feature:

- This system comes with a SS spray both capable to hold 3 mannequins. A conveyor with hanging mannequin and hot chamber comes standard.

- The hot chamber ensures faster drying of PP hence no need to keep garment in waiting position for longer time.

- There is no risk of getting PP spots on the garment as it will come out in a dry condition.

- The productivity is higher compared to a traditional spray booth.

Technical Specification

| Model | Capacity | Blower | Water | Total power | Air | Dimension | Approx |

|

|

|

| Pump | Consumption | Requirement | (WxDxH) | Weight |

|

|

| (hp) | (hp) | (hp) |

| (mm) | (kgs) |

| RSB 072 | 2 Mannequins | 3 | 1 | 4 | 16 CFM | 2980x2140x3150 | 900 |

| RSB 073 | 3 Mannequins | 5 | 1 | 6 | 21 CFM | 3720x2140x3300 | 1250 |

| RSB 074 | 4 Mannequins | 7.5 | 3 | 10.5 | 26 CFM | 4720x2040x3350 | 1400 |

| RSB 075 | 5 Mannequins | 7.5 | 3 | 10.5 | 31 CFM | 5720x2040x3350 | 1600 |

| RSB 076 | 6 Mannequins | 7.5 | 3 | 10.5 | 36 CFM | 6720x2040x3350 | 1850 |

High Efficiency & Precision Coating

Outfitted with four advanced air-assisted nozzles, this system guarantees optimal paint distribution and reduced wastage. The adjustable conveyor speed allows operators to customize workflow, catering to varied application requirements and ensuring consistent, quality finishes on every unit.

Safety & Environmental Compliance

This spraying solution prioritizes operator safety with integrated emergency stop mechanisms, safety interlocks, and protective covers. Built to adhere to ISO 14001 environmental standards, it supports responsible operations for exporters, importers, manufacturers, and suppliers across India, reducing workplace hazards and environmental impact.

Intuitive Control & Easy Maintenance

Equipped with a PLC-based control panel, the system enables seamless adjustment of spray intervals and conveyor speed. Maintenance is simplified by an integrated auto-rinse cycle and removable spray nozzles, ensuring the equipment remains clean and fully operational with minimal downtime.

FAQs of Conveyorised Spraying System:

Q: How does the conveyorised spraying system ensure uniform paint application?

A: The system employs four high-efficiency air-assisted spray nozzles, precisely positioned along a continuous belt conveyor. The PLC-based automated control panel allows for accurate adjustment of spray timing, ensuring even and consistent coating across all surfaces.Q: What types of paints are compatible with this spraying system?

A: This system is designed for versatility and supports both water-based and solvent-based paints, making it adaptable to various industry-specific coating requirements.Q: When should the integrated auto-rinse cleaning cycle be used?

A: It is recommended to use the integrated auto-rinse cycle after each production run or when switching paint types. This helps prevent clogging, maintains spray quality, and extends the longevity of spray nozzles.Q: Where can this conveyorised spraying system be installed?

A: The modular assembly enables installation in manufacturing plants or workshops with solid flooring. It requires a suitable power sourceeither single-phase or three-phasemaking it ideal for diverse industrial settings across India.Q: What is the operating temperature range and how is it managed?

A: The system is designed to operate in temperatures ranging from ambient to 70C. Built-in electric heating elements with an adjustable thermostat provide precise temperature regulation during coating processes.Q: How does the safety interlock and emergency stop enhance operator safety?

A: The safety interlock system ensures the conveyor stops immediately if safety covers are opened, while the emergency stop switch allows users to halt the entire process instantly in case of an emergency, minimizing risk to personnel.Q: What advantages does the polished, corrosion-resistant stainless steel construction offer?

A: The use of 304 grade stainless steel not only provides superior resistance to corrosion but also ensures an easy-to-clean, durable surface, guaranteeing long-term performance and a professional finish in demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dry Process Equipment Category

Multi Head Crinkling Machine

Capacity : 250300 kg/hr

Material : Stainless steel (SS 304 grade)

Voltage : 380V, 3 Phase, 50/60 Hz

Heating : Electric heating elements with temperature control

Cleaning Method : Manual and semiautomatic cleaning options

Installation Guideline : Onsite installation support with user manual and operational training

Flexi Brushing Robo (Vertical & Horizontal Robo)

Capacity : Up to 10 Drums per Hour

Material : Stainless Steel 304/316

Voltage : 415 V, 3 Phase, 50 Hz

Heating : Optional Electric or Steam Heating Arrangement

Cleaning Method : HighSpeed Rotary Brushing (Both Vertical and Horizontal Axis)

Installation Guideline : Easy to Install Plug & Play Modules with Customizable Mounts

Conveyor Curing Oven

Capacity : 200 2000 kg/hr (customizable)

Material : Mild Steel or Stainless Steel

Voltage : 415 V, 3 Phase, 50/60 Hz

Heating : Electric Heater or Optional Infrared

Cleaning Method : Manual interior cleaning, removable trays

Installation Guideline : Requires leveled ground, power supply connection and proper ventilation

GST : 29AAACR8787Q1Z6

|

RAMSONS GARMENT FINISHING EQUIPMENTS (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry