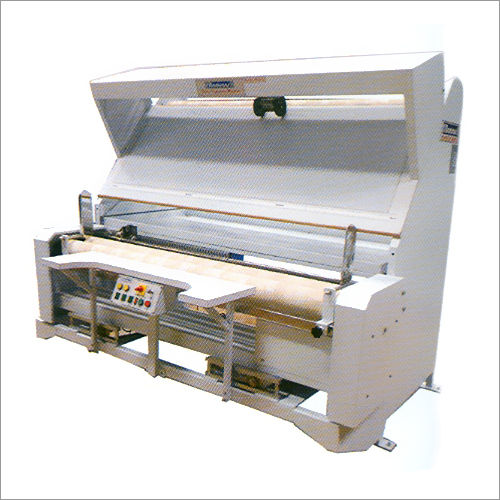

Fabric Inspection Machine

Fabric Inspection Machine Specification

- Drum Capacity

- Upto 150 Kg

- Drum Diameter

- 600 mm

- Heating

- No Heating Involved

- Voltage

- 220-380V, 50/60Hz

- Capacity

- Up to 100 meters/min

- Material

- Heavy Duty Mild Steel Frame

- Control System

- PLC Based Electronic Control

- Installation Guideline

- Floor Mounted, Easy to Install

- Cleaning Method

- Automatic Dust and Lint Removal

- Lighting

- High Intensity LED Inspection Light

- Edge Alignment

- Automatic Edge Aligner System

- Number of Rollers

- 4 Precision Steel Rollers

- Display

- Digital Meter and LCD Touch Panel

- Operation

- Forward/Reverse with Variable Speed Drive

- Brake System

- Electromagnetic Brake for Precise Stopping

- Power Consumption

- 1.5 kW

- Fabric Roll Width

- Maximum 1800 mm

- Dimension

- L 2500 mm x W 1100 mm x H 1600 mm

- Weight

- Approx 560 kg

About Fabric Inspection Machine

Fabric Inspection Machine (Rfi 01e, Rfi 01 E(Denim))

Basic fabric inspection machines

- Extra width for wide fabric material, suitable for any fabric material under 82'' width.

- The speed of the roller and the rocker has been adjusted and is controlled by control box.

- Inverse rolling direction for rolling back the problematic fabric material.

- With movable wheel for moving easily.

| Model | Viewing Glass | Fabric Width | Machine Speed | Gears Motor | Supply Voltage | Spreader Motor | Dimension (WxDxH) | Approx Weight |

|

| (inch) | (inch) | (mtrs/min) | (hp) |

| (hp) | (mm) | (Kgs) |

| RFI 01 | 72x21 | 65 | Variable up to 15 | 1 | 220v/50Hz/Single phase | NA | 2000x1950x1830 | 450 |

| RFI 01 E | 72x21 | 65 | Variable up to 15 | 1 | 220v/50Hz/Single phase | NA | 2000x2100x1830 | 490 |

Efficient Fabric Quality Control

This Fabric Inspection Machine enables thorough examination of textiles before dispatch. The integration of a high-intensity LED light, automatic edge alignment, and a digital display system ensures consistent and reliable identification of fabric defects, helping manufacturers maintain strict quality standards.

Advanced Electronic Controls

Powered by a PLC-based electronic system, the machine offers user-friendly operations via an LCD touch panel. Forward/reverse motion and variable speed drive facilitate flexible inspection speeds to suit different fabric types, maximizing productivity and reducing downtime during fast-paced production cycles.

FAQs of Fabric Inspection Machine:

Q: How does the automatic edge aligner benefit the inspection process?

A: The automatic edge aligner system ensures the fabric is consistently positioned during inspection. This precision minimizes wastage due to misalignment and helps in accurately detecting defects along the fabric edges.Q: What are the primary advantages of using high-intensity LED inspection lighting?

A: High-intensity LED lights provide uniform and bright illumination across the fabric surface, making it easier to spot imperfections, stains, or weaving faults, and enhancing the accuracy of quality control.Q: Where can this fabric inspection machine be installed?

A: The machine is designed for floor-mounted installation. Its robust frame and moderate footprint allow placement in textile manufacturing units, inspection sections, or export houses without complex foundation requirements.Q: What is the capacity and maximum roll width that this machine can handle?

A: It is capable of handling fabric rolls up to 1800 mm in width and processes fabric at speeds up to 100 meters per minute, accommodating high-volume textile operations.Q: How does the automatic dust and lint removal system work?

A: The built-in automatic cleaning system actively removes dust and lint throughout inspection, ensuring that fabric surfaces remain clear for accurate evaluation and reducing manual cleaning efforts.Q: When should maintenance be performed on the machine?

A: Regular maintenance, such as checking roller alignment and cleaning the LED lights, is recommended according to the manufacturers guidelines. The automatic cleaning system reduces daily upkeep, but periodic inspection ensures long-term performance.Q: What materials are used in the construction of this inspection machine?

A: The machine is fabricated from heavy duty mild steel, providing strength, durability, and resistance to wearcrucial for frequent industrial use in export, import, and manufacturing environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Co - Related Machine Category

Single Head Needle Detector

Installation Guideline : Easy to Install on Conveyor Line

Control System : Microcomputer Control

Material : HighGrade Steel and ABS Plastic

Voltage : 220V / 50Hz

Cleaning Method : Manual

Capacity : Up to 6000 pcs/hour

Basic Fabric Inspection Machine

Installation Guideline : Easy installation with adjustable frame and leveling system

Control System : Manual and semiautomatic options available

Material : Heavyduty mild steel with powder coating

Voltage : 220V / 380V, 50Hz, single or three phase

Cleaning Method : Manual cleaning; smooth surface for easy lint removal

Capacity : 50100 meters/min fabric speed

Dual Head Needle Detector

Installation Guideline : Easy Installation, Plug & Play

Control System : Microprocessor Based

Material : Mild Steel Body with Powder Coating

Voltage : 220V AC, 50Hz

Cleaning Method : Automatic Conveyor Cleaning

Capacity : Up to 30,000 pieces/hour

Thread Sucking Machine

Installation Guideline : Refer to manufacturers guidelines

Control System : Manual

Material : Steel

GST : 29AAACR8787Q1Z6

|

RAMSONS GARMENT FINISHING EQUIPMENTS (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry