Dual Head Needle Detector

Dual Head Needle Detector Specification

- Heating

- No Heating Required

- Voltage

- 220V AC, 50Hz

- Capacity

- Up to 30,000 pieces/hour

- Material

- Mild Steel Body with Powder Coating

- Control System

- Microprocessor Based

- Installation Guideline

- Easy Installation, Plug & Play

- Cleaning Method

- Automatic Conveyor Cleaning

- Application

- Textile, Garments, Socks, Towels

- Alarm System

- Audio-Visual Alarm on Needle Detection

- Detection Width

- 600mm

- Power Consumption

- Approx. 60W

- Conveyor Type

- Anti-static PVC Belt Conveyor

- Operating Temperature

- 0°C - 40°C

- Detection Head

- Dual Head for Enhanced Accuracy

- Display

- Digital LED Display

- Detection Height

- 100mm

- Detection Sensitivity

- 0.8mm (Standard), Adjustable

About Dual Head Needle Detector

Dual Head Needle Detector

Features:

- When the sensor detects a broken needle pin or a 1mm needle chip, a buzzer will automatically sound and the conveyor belt will stop.

- The machine is available in two modes of operation: Production and Test card

- 10 indicator lamps identify the exact location of a foreign object.

- The control panel is equipped with a safety lock.

- A protection cover is available for the control panel so as not to hit the sensitivity level or change the mode of operation by accident.

| Model | Detection Ability | Detection | Detection | Detection | Alarm | Voltage | Power | Dimensions | Weight |

|

| Steel Ball Standard | Adjustment | Width | Height |

|

|

| (LxBxH) |

|

|

| (dia in mm) | Grade | (mm) | (mm) |

| (volts) | (w/h) | (mm) | (kgs) |

| RAM 520 ND | >1.0 | 1-10 | 610 | 100,125,150,200 | Double Sound | 200 | 100 | 1650x1050x900 | 180 |

Dual Head Detection for Optimal Accuracy

Equipped with two detection heads, this needle detector effectively increases detection coverage and accuracy, reducing the risk of missing broken needle fragments. Ideal for quality control in textile and garment industries, the dual head design helps maintain product safety and meet compliance standards.

Adjustable Sensitivity & User-Friendly Operation

Operators can easily adjust the sensitivity to detect needles as small as 0.8mm, ensuring adaptability for different product requirements. The intuitive digital LED display and automatic cleaning mechanism simplify monitoring and maintenance, while plug-and-play installation enables hassle-free setup.

Robust Construction & High-Capacity Performance

Built with a powder-coated mild steel body for durability, this detector handles up to 30,000 pieces per hour. It operates efficiently at 220V AC, 50Hz, without requiring heating, making it energy-saving and suitable for large-scale production environments.

FAQs of Dual Head Needle Detector:

Q: How does the dual head system enhance needle detection accuracy?

A: The dual head configuration expands the detection zone, allowing for more thorough scans of textiles and garments. This reduces the chance of undetected needle fragments, ensuring greater product safety during quality control checks.Q: What is the process for installing the Dual Head Needle Detector?

A: Installation is straightforward and requires minimal technical expertise. The machine features a plug-and-play system, allowing users to set it up quickly without the need for complex wiring or adjustments.Q: When should I adjust the sensitivity settings?

A: Adjust sensitivity based on the size and material of the items being inspected. For finer textiles or products where smaller needle fragments are a concern, increase the sensitivity to detect particles down to 0.8mm.Q: Where is this needle detector best used?

A: It is designed for textile mills, garment factories, sock and towel manufacturers, and anywhere precise detection of needle fragments in finished goods is necessary for safety and compliance.Q: What benefits does the anti-static PVC belt conveyor offer?

A: The anti-static PVC belt conveyor minimizes static buildup, reducing the risk of fabric damage and ensuring smooth, consistent movement through the detection zone for accurate scanning.Q: How does the automatic conveyor cleaning work?

A: The machine is equipped with a system that cleans the conveyor automatically, minimizing maintenance requirements and ensuring consistent detection performance without manual intervention.Q: Is there any heating required for operation?

A: No heating is required. The detector operates efficiently within 0C to 40C, making it suitable for diverse manufacturing environments while reducing energy consumption and operational costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Co - Related Machine Category

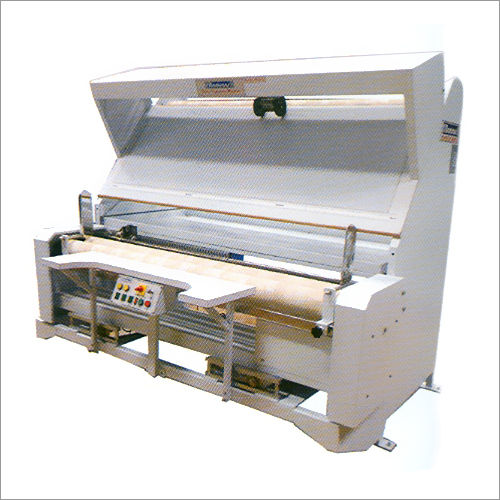

Knits/Woven Fabric Inspection Machine

Installation Guideline : Floor mounted, easy to assemble with provided instruction manual

Control System : PLC based with touch screen interface

Material : Powder coated steel structure

Voltage : 220V / 380V, 50/60 Hz

Cleaning Method : Manual and automatic brush cleaning system

Drum Diameter : 450 mm

Fabric Inspection Machine

Installation Guideline : Floor Mounted, Easy to Install

Control System : PLC Based Electronic Control

Material : Heavy Duty Mild Steel Frame

Voltage : 220380V, 50/60Hz

Cleaning Method : Automatic Dust and Lint Removal

Drum Diameter : 600 mm

Knits Fabric Inspection Machine

Installation Guideline : Floor Mounted, Simple Installation

Control System : PLC Controlled / Digital / Manual

Material : Mild Steel with powder coating

Voltage : 220240 V, Single Phase

Cleaning Method : Manual and Auto Cleaning Options

Drum Diameter : 600 mm

Single Head Needle Detector

Installation Guideline : Easy to Install on Conveyor Line

Control System : Microcomputer Control

Material : HighGrade Steel and ABS Plastic

Voltage : 220V / 50Hz

Cleaning Method : Manual

Drum Diameter : 180 mm

GST : 29AAACR8787Q1Z6

|

RAMSONS GARMENT FINISHING EQUIPMENTS (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry