Seam Buster RV 500

Seam Buster RV 500 Specification

- Drum Diameter

- 500 mm

- Drum Capacity

- 50 Liters

- Heating

- Electric Heating Element

- Voltage

- 220 V AC

- Capacity

- 40-50 Kg/Batch

- Material

- Stainless Steel 304

- Control System

- PLC Controlled

- Installation Guideline

- Easy to install, comes with user manual

- Cleaning Method

- Automatic Jet Cleaning

- Application

- For Removing External Seam of Cashew Nuts

- Automation Grade

- Semi Automatic

- Dimensions (LxWxH)

- 900 x 650 x 1250 mm

- Weight

- Approx. 130 Kg

- Motor Power

- 2 HP

- Finish Type

- Polished

- Cycle Time

- 20-30 minutes per batch

- Safety Features

- Emergency Stop Button, Overload Protection

About Seam Buster RV 500

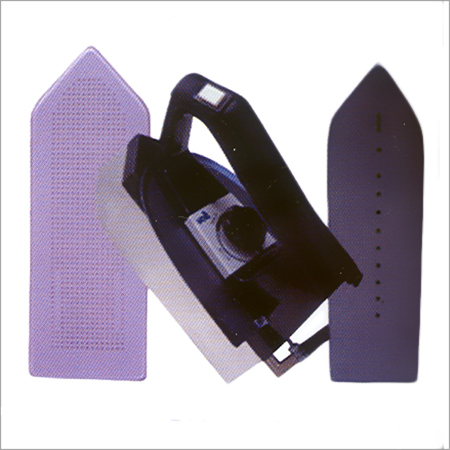

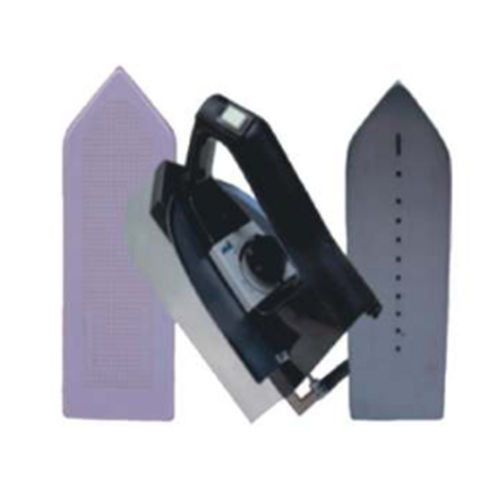

- This slim press is used to bust seams on trousers and sleeves

- Temperature tolerance of +/-2 C facilitates pressing

Specification

|

Model |

Temp. |

Weight |

Temp. Tolerance |

|

|

(degrees C) |

(kgs) |

(degrees C) |

|

RV 500 |

0-235 |

1.9 |

2 |

Superior Seam Removal Technology

With its semi-automatic function, the Seam Buster RV 500 efficiently removes external seams from cashew nuts. The machine's polished finish ensures hygiene, and its electric heating system guarantees optimal results without manual intervention. Designed for reliability, it helps minimize labor and improves quality in cashew processing operations.

Safety and Automation Features

Equipped with advanced safety features like an emergency stop button and overload protection, the Seam Buster RV 500 maintains operator safety throughout use. Its PLC-controlled system enhances precision, while automatic jet cleaning simplifies maintenance, creating a user-friendly and low-risk work environment in any industrial setting.

Easy Installation and Maintenance

Installation of the RV 500 is straightforward, guided by a comprehensive user manual. Designed for hassle-free setup, the unit's automatic jet cleaning function further reduces maintenance efforts. This combination allows businesses to integrate the Seam Buster quickly and maintain it with minimal disruption to their workflow.

FAQ's of Seam Buster RV 500:

Q: How does the Seam Buster RV 500 operate for removing cashew nut seams?

A: The Seam Buster RV 500 uses a PLC-controlled, semi-automatic process to efficiently remove external seams from cashew nuts. After loading the batch, the drum spins and the heating element activates, helping to separate seams while ensuring a polished finish.Q: What is the process for cleaning the machine after use?

A: The RV 500 features an automatic jet cleaning method. Upon completion of a batch, the system uses jets to wash residue from the drum, making cleaning easy and quick, thereby reducing manual maintenance requirements.Q: When should the emergency stop button be used?

A: The emergency stop button on the Seam Buster RV 500 should be used immediately if any unexpected malfunction, blockage, or safety concern arises during operation. This ensures the safety of operators and prevents machine damage.Q: Where can the Seam Buster RV 500 be installed and operated?

A: This machine is suitable for installation in commercial cashew processing facilities, such as exporter, importer, manufacturer, or supplier settings within India. Its compact dimensions and easy installation guidelines allow it to fit seamlessly into most industrial spaces.Q: What is the batch capacity and cycle time for each operation?

A: The Seam Buster RV 500 can process 40-50 kg of cashew nuts per batch, with each cycle lasting approximately 20-30 minutes, depending on nut conditions and desired output.Q: How does the PLC control system benefit the user?

A: The PLC (Programmable Logic Controller) control system provides precise automation, ensuring consistent removal results, improved safety, and simplified operation for the user, minimizing human error and enhancing productivity.Q: What safety features are included with the Seam Buster RV 500?

A: Key safety features of the RV 500 include an emergency stop button and overload protection, both designed to safeguard the operator and the machine during processing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electric / Steam Press Category

Steam Buster Press

Control System : Digital control panel

Installation Guideline : Refer to the installation manual provided

Material : Stainless steel

Voltage : 220V 50Hz

Heating : Electric

Cleaning Method : Manual

High Pressur Iron

Control System : Analog control

Installation Guideline : Pluganduse installation

Material : Stainless steel and plastic

Voltage : 220V

Heating : Electric heating

Cleaning Method : Manual cleaning

Professional Steam Iron

Control System : Manual control with temperature adjustment dial

Installation Guideline : Plug and use no complex installation required

Material : Stainless Steel

Voltage : 220240V

Heating : Electric heating element

Cleaning Method : Manual cleaning

High Pressure Iron

Control System : Manual Dial Control

Installation Guideline : Plug and use with standard electrical outlet

Material : Metal (Stainless Steel) and Plastic

Voltage : 120V / 220V

Heating : Electrical

Cleaning Method : Manual

GST : 29AAACR8787Q1Z6

|

RAMSONS GARMENT FINISHING EQUIPMENTS (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry